Updated 2022

DC HO MOTORS

Where Speed Lives ...

Tips and Common Sense

Building Chassis's:

The performance of your car depends on how well you build it. When installing an

armature always insure there is ample vertical play between the gearplate and the

chassis tub. Be very careful if you are using shims to reduce this vertical play.

High performance armatures can run warm. Sufficient vertical play will allow for heat

expansion of the armature. If this play is not sufficient, armature binding can happen

causing friction and possible destruction of the armature and chassis. Install high

performance armatures in well built chassis's only. Do not use old brushes. Always use

a new set of brushes whenever you install a new armature and make sure you adjust

the brush spring tension properly. Too much tension can cause an armature to

overheat. To little tension can cause decreased performance and arcing which in itself

can cause overheating. DO NOT USE BEVELED BRUSHES! I have seen brushes

melted right into chassis's because of the use of crappy parts. New brushes are cheap,

use them.

DO NOT RUN THESE MOTORS IN AUTOWORLD CHASSIS.

Your Business Website

Your Company Slogan Here ...

Some Words On Magnets

All of the Road Race Motors can run with most moderate strength magnets. The more

powerful the magnet, the more power the motor will put out.

IMPORTANT - WATCH OUT!!! A MAGNET THAT IS TOO STRONG MAY ACTUALLY

REDUCE A MOTORS PERFORMANCE, AND DAMAGE THE MOTOR. START WITH A

WEAK MAGNET AND STEP UP STRONGER TO ACHIEVE THE PERFORMANCE YOU

DESIRE, BUT ALWAYS PAY ATTENTION TO THE HEAT THAT IS GENERATED.

STRONGER MAGNETS WILL CAUSE A MOTOR TO HEAT UP FASTER AND FAIL.

BEWARE - OVERLY STRONG MOTOR MAGNETS, AND ADDING TRACTION

MAGNETS TO YOUR CHASSIS HAS THE POTENTIAL TO OVERHEAT YOUR MOTOR

AND CAUSE HARM TO THE MOTOR AND CHASSIS.

Drag Race Motors need more powerful magnets. Poly or Neo Magnets are

recommended. The more powerful the magnet, the more speed and torque the motor will

put out. You may need to experiment with different types of magnets to achieve the results

you want from these motors.

TRACTION MAGNETS - ALTHOUGH THESE MAGNETS ARE GREAT AT PROVIDING

THE STICTION YOU NEED FOR DRAG RACING, THEY DO PUT A STRAIN ON THE

ARMATURE. WHEN USING TRACTION MAGNETS PAY CLOSE ATTENTION TO THE

HEAT THAT IS GENERATED BY THE MOTOR. YOU DON'T WANT A MELTDOWN.

Armature Handling

Handle your armature carefully.

Always use a quality armature installation tool to remove and install armatures. Never

apply any force to the commutator plate. Any excessive force can cause the

commutator plate to move out of alignment causing decreased performance.

Nicks or dents in the wire windings can decrease performance and render an armature

non-functional. Just be careful with them ok.

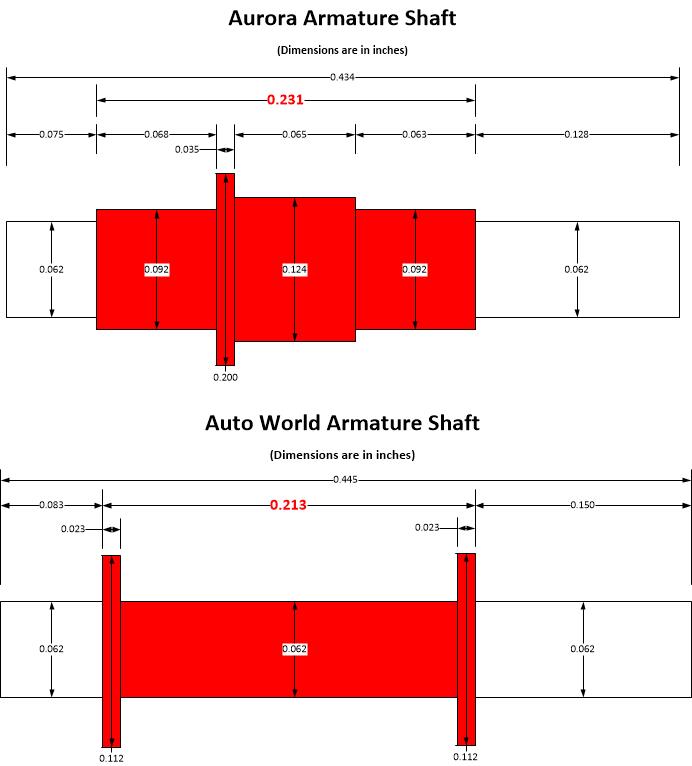

The Difference between Vintage Aurora and AW Armature Shafts

All pancake armatures, and the chassis's that run them are not created equal. The

armature cavity height in an AW chassis is slightly different than a vintage Aurora chassis.

The usable height in an AW chassis is shorter than in a vintage Aurora chassis. If you try

to install an Aurora armature in an AW chassis the gear plate may distort (bow up) once

the gear plate is installed and secured with the gear plate clip. This is because the motor

is too tall for the chassis. When the chassis is energized, this binding will cause friction

and heat, which will cause damage to the chassis. Don't modify the hole in the gearplate

to compensate for this because the wire wraps may rub on the underside of the gearplate

and may damage the wires.

You can see this in the armature shaft illustration below. The dimension in RED is the one

of concern.

Armature Oiling

Please don't over oil the armature! Use a good quality oil, there are many out there. I

am not going to recommend any one oil to use, but for the lower bearing hole use an oil

that is going to stay in place and not migrate to the commutator plate and brushes.

Armatures and chassis's can be ruined because of over-oiling using thin oils or the use

of "Comm Drops". Strive to keep the commutator plate clean and free of oils or other

contaminants. A little bit of oil goes a long way.